summary

Red clay bricks are much durable and hard material for construction. The raw material for making of red clay brick is easily available and the maintenance cost is very low or minimal. Strength of red bricks are better than other bricks and construction stuff. It has very special thing that it helps your home or building keep cool in summer and warm in winters. Red bricks are very popular material part in Indian construction because these are eco friendly and less polluted materials. Red bricks are more profitable for customers and also for local contractors.

More About Red Clay Bricks

Red clay bricks are a mixture of natural clay, sand, water, and other additives that make it solid after some process. Red bricks are the most important construction material to make new houses, buildings, etc. They are commonly used for constructing walls, overhead or underground water tanks, commercial or residential buildings, etc.

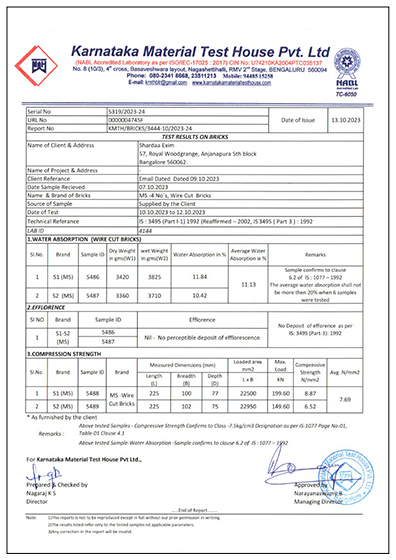

Shardaa Exim is a leading and well-known Karnataka-based red brick manufacturer, supplier, and exporter. We are dealing in red brick wholesale supply in India.

Benefits of Red Clay Bricks

- Red clay bricks are more durable than other bricks, red bricks are able to withstand extreme weather conditions, fire, and wear. They have a long lifespan, often outlasting the structures they are part of.

- As a natural material, red clay bricks are pure eco-friendly. The production process requires minimal energy compared to other building materials, and the bricks can often be recycled or repurposed.

- The color of red clay bricks is very natural and traditionally with modern shades. They can be used for a rustic, classic look or a contemporary finish, depending on the design.

- Once red bricks installed, it is require minimal maintenance. They are resistant to rot, pests, and decay, unlike wood or other materials.

Challenges of Red Clay Bricks

- There are many challenges to face while manufacturing red clay bricks

- Red clay bricks are relatively heavy and its most challenging part of it, which can make handling and transportation more difficult and costly compared to lighter alternatives like concrete blocks or lightweight bricks.

- While they are weather-resistant, red clay bricks can absorb water if not fit with cement.

- The manufacturing process, especially firing the bricks in heating system, can be labor and energy taking to make, leading to higher production costs and a greater environmental footprint compared to more industrialized materials.

Red Clay Bricks are very reliable and attractive choice for any kind of construction weather its rural or city because of their durability, low maintenance, cheaper. Brick’s long-lasting nature and capacity to insulate heat and sound make them unique and most demanding construction material for various types of projects. There are lots of benefits red clay bricks offer but the manufacturing process requires careful handling and energy.

Careful Soil Selection and Mixing

Qualitative Handmade Bricks

Sun Dried Before Firing

Drying Under The Sun

Ready To Be Used For Construction

Closed Kiln

Ready Bricks for Export

- Selection Of Soil From 3-4 Sources And Clay Is Well Mixed, And Left For Ageing, Thereafter Mixed With Powdered Coal And Rice Husk In Limited Quantities And Then Fired Makes The Brick Very Strong

- Curated soil, Overnight Soaking and Mixing Of Clay Gives The Bricks It Load Bearing Strength And Durability

- Use Of Mix Fuel- Coal And Rice Husk Gives Strength And Red Natural Colour The Red Brick